arrow_back_ios

Main Menu

arrow_back_ios

Main Menu

- DAQ

- Drivers API

- nCode - Durability and Fatigue Analysis

- ReliaSoft - Reliability Analysis and Management

- Test Data Management

- Utility

- Vibration Control

- Inertial Sensor Software

- Acoustic

- Current / voltage

- Displacement

- Schwingungserreger

- Force

- Inertialsensoren

- Wägezellen

- Multi Component

- Pressure

- Smarte Sensoren mit IO-Link-Schnittstelle

- Strain

- Temperature

- Tilt

- Torque

- Vibration

- DAQ-Systeme für mechanische Belastungen und Strukturüberwachung

- DAQ-Systeme für Schall- & Schwingungsmessungen

- Industrie-Elektroniken

- Leistungsanalysatoren für elektrische Systeme

- Handgehaltene Geräte für Schall und Schwingung

- Drahtlose DAQ-Systeme

- DAQ-Systeme für mechanische Belastungen und Strukturüberwachung

- High Precision and Calibration Systems

- Akustik

- Anlagen- und Prozessüberwachung

- Elektrische Energie

- Kundenspezifische Sensoren

- NVH

- Zuverlässigkeit

- Smarte Sensoren

- Schwingbelastung

- Virtuelle Tests

- Strukturelle Integrität

- Wägetechnik

- Calibration

- HBK Assured Service Contracts

- Installation, Maintenance & Repair

- Fatigue Testing Lab & Materials Characterisation - HBK

arrow_back_ios

Main Menu

- BK Connect / PULSE

- catman Enterprise

- catmanEasy AP

- Software Downloads for Perception / Genesis HighSpeed

- Tescia

- Catman data acquisition software

- Thousands of Channels at a Glance

- High speed data acquisition software perception

- Drivers for compatibility with third party software

- ReliaSoft BlockSim

- ReliaSoft Cloud

- ReliaSoft Lambda Predict

- ReliaSoft Product Suites

- ReliaSoft RCM++

- ReliaSoft XFMEA

- ReliaSoft XFRACAS

- ReliaSoft Weibull++

- Classical Shock

- Random

- Random-On-Random

- Shock Response Spectrum Synthesis

- Sine-On-Random

- Time Waveform Replication

- Vibration Control Software

- Microphone sets

- Cartridges

- Referenzmikrofone

- Spezialmikrofone

- Kits für akustische Materialprüfungen

- Akustische Kalibratoren

- Hydrofone

- Mikrofon-Vorverstärker

- Schallquellen

- Zubehör für akustische Sensoren

- Inertial Measurement Units (IMU)

- Vertikale Referenzeinheiten (VRU)

- Lage- und Kurs-Referenzsysteme (AHRS)

- Inertialnavigationssysteme (INS)

- Zubehör für Inertialsensoren

- Bending / beam

- Canister

- Compression

- Single Point

- Tension

- Wägemodule

- Digitale Wägezellen

- Zubehör für Wägezellen

- DMS für die Experimentelle Spannungsanalyse

- Optische DMS

- DMS für den Aufnehmerbau (OEM)

- Dehnungssensoren

- Zubehör für Dehnungsmessstreifen

- CCLD (IEPE)-Beschleunigungssensor

- Ladungs-Beschleunigungssensor

- Faseroptischer Beschleunigungssensor

- Kraftaufnehmer

- Referenz-Beschleunigungssensor

- Impulshämmer / Impedanzköpfe

- Drehzahlsensoren

- Schwingungskalibratoren

- Kabel

- Zubehör für Schwingungssensoren

- Accessories

- QuantumX

- SomatXR

- MGCplus

- Optische Interrogatoren

- CANHEAD

- eDAQ

- DMS-basiertes Präzisionsmessgerät

- Brückennormale

- LAN-XI

- Fusion-LN

- CCLD (IEPE)-Konditionierverstärker

- Ladungskonditionierverstärker

- Mikrofonkonditionierverstärker

- NEXUS

- Mikrofonkalibriersystem

- Kalibriersystem für Schwingungssensoren

- Kalibriersystem für Schallpegelmesser

- Zubehör für Konditionierverstärker

- Zubehör für Kalibriersysteme

- Mehrkanalsystem

- Einkanal-Messverstärker und Messverstärker mit Anzeige

- Wägeindikatoren

- Wägeelektronik

- Zubehör für Industrieelektroniken

- Wägeelektronik

- Wägeindikatoren

- eDrive-Paket

- eDrive Package - Remote Probe based

- eGrid-Paket

- GenHS

- Zubehör für Leistungsanalysator und GenHS

- Schallpegelmesser

- Schwingungsmessgeräte

- Software für handgehaltene Geräte

- Zubehör für handgehaltene Geräte für Schall und Schwingung

- Zubehör

- Aktoren

- Verbrennungsmotoren

- Betriebsfestigkeit

- eDrive

- Mobile Systeme

- Sensoren für Produktionstests

- Getriebe

- Turbolader

- HATS (Kopf- und Rumpfsimulator)

- Künstliches Ohr

- Elektroakustik-Hardware

- Knochenleitung

- Elektroakustik-Software

- Ohrmuscheln

- Zubehör für Elektroakustikanwendungen

- Akustik und Schwingungen

- Anlagen- und Prozessüberwachung

- Datenakquisition

- Elektrische Maschinen und Leistungselektronik

- Ermüdungs- und Lebensdaueranalysen

- Mechanisches Testen und Prüfen

- Wägetechnik

- Elektroakustik

- Schallquellenortung

- Umgebungslärm

- Produkt-Lärm

- Rampengeräuschprüfung

- Zertifizierung statischer Motorengeräusche

- Schallleistung und Schalldruck

- Flugzertifizierung

- Akustische Materialprüfung

- Vorbeifahrgeräusche

- Industrielle Prozesskontrolle

- Strukturüberwachung

- Produktionsprüfung und Qualitätssicherung

- Maschinenanalyse und -diagnose

- Strukturüberwachung

- Prüfungen von Schaltanlagen

- Hochspannung

- Erprobung von Antriebssträngen

- Batterieprüfung

- Elektrische Maschinenprüfung | Powertrain Testing | HBM

- Einführung in die Messung elektrischer Leistung bei transienten Vorgängen

- Transformator-Ersatzschaltbild | HBM

- Aktuelle Nulltests

- Netzprüfung | Schaltanlagenprüfung | Lösungen | HBM

- Tests im Antriebsstrang

- Schaltgeräte-Tests

- OEM Custom Sensorbaugruppen für eBikes

- OEM kundenspezifische Sensorbaugruppen für die Agrarindustrie

- Kundenspezifische OEM-Sensor-Baugruppen für medizinische Anwendungen

- Kundenspezifische Sensorbaugruppen für Robotic OEM

- Dauerhaftigkeitsprüfung - Ermüdungsprüfung

- Schock- und Falltests

- Verpackungsprüfung / Transportschwingungen

- Umweltstress-Screening - ESS

- Mechanische Satellitenqualifikation

- Buzz, Squeak und Rattle (BSR)

- Batterieprüfung für Elektro- und Hybridfahrzeuge

- Strukturelle Dynamik

- Strukturelle Dauerhaftigkeit und Ermüdungsprüfung

- Prüfung der Materialeigenschaften

- Sicherstellung der strukturellen Integrität von Leichtbaustrukturen

arrow_back_ios

Main Menu

- Binaurales Audio

- Außenmikrofone

- Probe Microphones

- Schallintensitätssonden

- Oberflächenmikrofone

- Array-Mikrofone

- Weitere Spezialmikrofone

- Mikrofone für Prüfungen an Fertigungsstraßen

- Sondenmikrofone

- Mikrofonkabel

- Stative

- Mikrofonarm

- Mikrofonadapter

- Elektrostatische Aktoren

- Mikrofonwindschirm

- Nasenkonus

- Mikrofonhalter

- Stative

- Weiteres Zubehör für akustische Sensoren

- Mikrofonschutz für den Außeneinsatz

- DC Statische Zentriereinheit

- Stromversorgung für den Feldeinsatz

- Trunnions

- Aufstellbügel für Schwingerreger

- Kabel

- Stinger

- Gelenkköpfe

- Zugkrafteinleitungen (nach ISO 376)

- Druckstücke und Lastknöpfe

- Kabel und Steckverbinder

- Schrauben-Sets

- Fußadapter / Zug/Druck-Adapter

- Messkabel

- Erdungskabel

- Druckstücke

- Lager

- Lastfüße

- Bodenplatten

- Gelenkösen

- Adapter

- Einbauhilfen und weiteres Zubehör

- Klebstoffe

- Abdeckmittel

- Reinigungsmaterial

- DMS-Kits

- Lötstützpunkte

- Weiteres Zubehör für DMS

- Kabel

- Nullpunktabgleich

- TKC-Abgleich

- TK0-Abgleich

- Magnete

- Befestigungsclips/-sockel

- Bolzen, Schrauben und Unterlegscheiben

- Klebstoffe/Werkzeug

- Adapter

- Mechanische Filter

- Weiteres Zubehör

- Gehäuse

- Kommunikationsprozessor

- Verstärkermodule

- Anschlussplatten

- Spezialeinschübe

- Zubehör für MGCplus

- G-Link-200

- G-Link-200-OEM

- SG-Link-200

- SG-Link-200-OEM

- V-Link-200

- RTD-Link-200

- TC-Link-200

- TC-Link-200-OEM

- Testen von Freisprecheinrichtungen

- Prüfung von Smart Speakern

- Lautsprecher-Tests

- Testen von Hörgeräten

- Kopfhörer-Test

- Testen von Telefon-Headsets und -Mobilteilen

- Akustische Holographie

- Verwaltung akustischer Signaturen

- Underwater Acoustic Ranging

- Akustische Tests im Windkanal — Luft- und Raumfahrt

- Windkanalprüfung für Autos

- Beamforming

- Fragen

- Identifizierung von Überfluglärmquellen

- Echtzeit-Identifizierung von Lärmquellen mit akustischer Kamera

- Abbildung der Schallintensität

- Sphärisches Beamforming

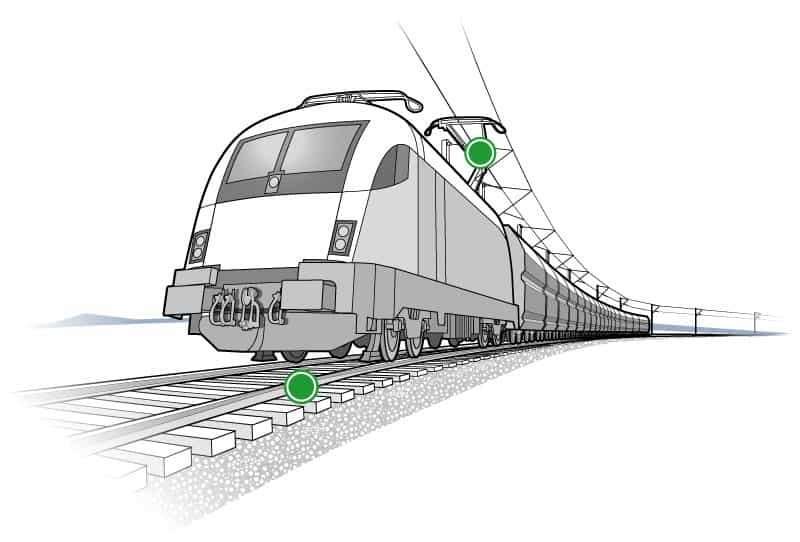

- Eisenbahn-Monitoring

- Tunnelüberwachung mit Faser-Bragg-Sensoren

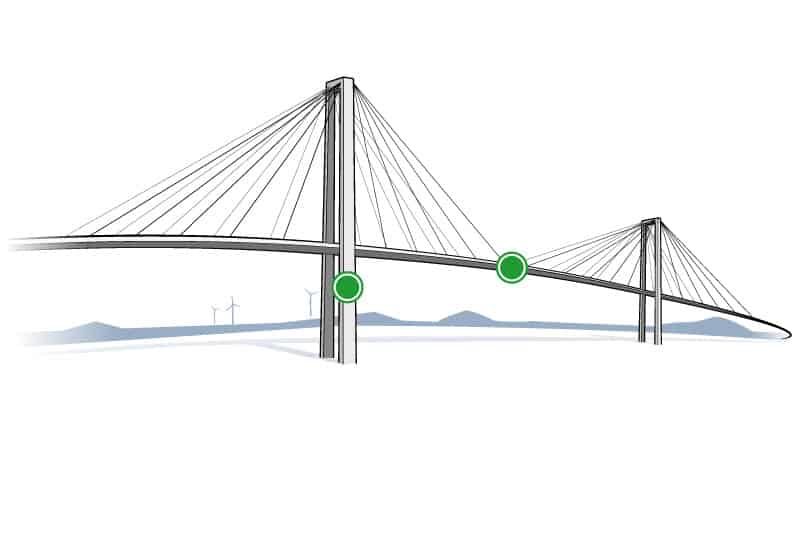

- Monitoring-Lösungen für zivile Infrastrukturen

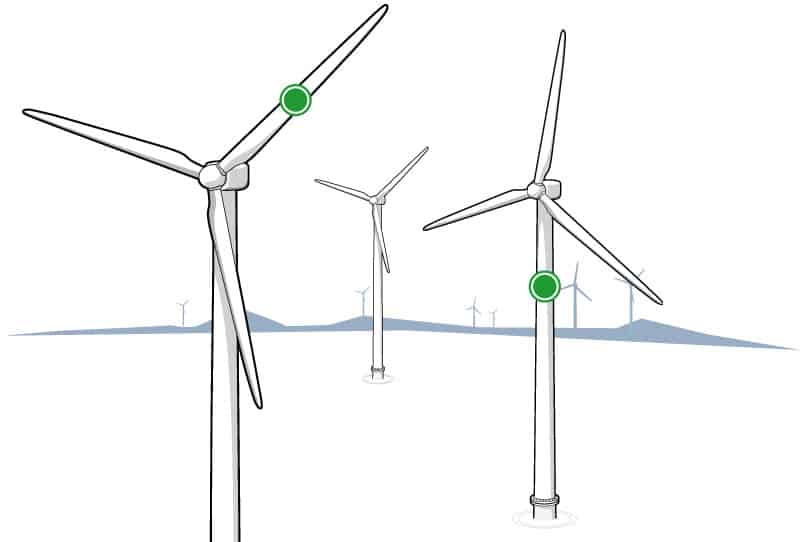

- Überwachungslösungen für Windturbinen

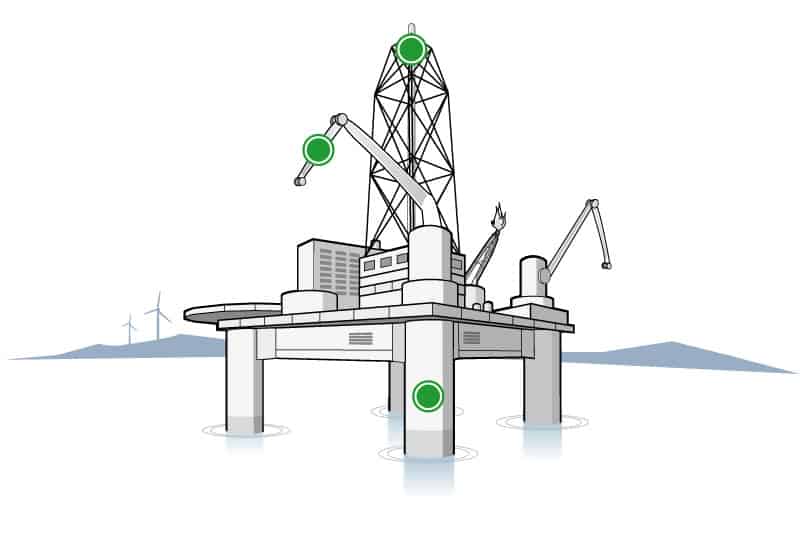

- Überwachungslösungen für die Öl- und Gasindustrie

- Überwachungslösungen für Eisenbahnen

- Überwachungslösungen für den Tiefbau

- Verfügbare Monitoring Services

- Fundamentüberwachung mit Dehnungsmessstreifen

- Auftragsanalyse

- Maschinendiagnose

- Gesundheits- und Nutzungsüberwachungssysteme (HUMS)

- Gasturbinenprüfung

- Fragen zur maschinellen Analyse

- Tunnel-Monitoring mit optischen Sensoren

- Monitoring-Lösungen für zivile Infrastrukturen

- Überwachungslösungen für Windturbinen

- Überwachungslösungen für die Öl- und Gasindustrie

- Überwachungslösungen für den Schienenverkehr

- Überwachungslösungen für das Bauwesen

- Verfügbare Monitoring-Services

- Fundamentüberwachung mit Dehnungsmessstreifen

- Mechanische Batterieprüfung mit Kraftsensoren

- Batterietests in der eMobilität

- Batterieprüfung in der Elektromobilität

- Mechanische Batterieprüfung mit Kraftsensoren

- Betriebsablenkungsformen (ODS)

- Klassische Modalanalyse

- Bodenvibrationstest (GVT)

- Operative Modalanalyse (OMA)

- Strukturelle Gesundheitsüberwachung (SHM)

- Test-FEA-Integration

- Schock-Reaktions-Spektrum (SRS)

- Strukturdynamische Systeme

- Fragen zur Strukturdynamik?

- Experimentelle Eigenspannungsanalyse mit dem Loch-Dril

- QuantumX Integration in ZwickRoell Prüfmaschine

- Eigenspannungen | Eigenspannungsmessung

- Elektrifizierung - Statistische Aspekte und Zuverlässigkeit (NEU)

- Elektrifizierung - Elektrische und signalverarbeitende Aspekte (NEU)

- Elektrifizierung — Mechanische und Haltbarkeitsaspekte (NEU)

- Elektrifizierung (NEU) - Auslegung und Prüfung der Lebensdauer von Strukturen für Elektrofahrzeuge

- "Elektrifizierung (NEU) - Elektrifizierung: Gewährleistung der Betriebsfestigkeit, Zuverlässigkeit und Leistung von Elektrofahrzeugen"

- Elektrifizierung (NEU) - Elektrische und Signal Nachbearbeitungstechniken für die Wechselstromanalyse in Elektrofahrzeugen

- Elektrifizierung (NEU) - Anwendung statistischer und Zuverlässigkeitstechniken zur Bestimmung der Batterielebensdauer in Elektrofahrzeugen

- Force Calibration

- Torque Calibration

- Microphones & Preamplifiers Calibration

- Accelerometers Calibration

- Pressure Calibration

- Displacement Sensor Calibration

- Sound Level Meter Calibration

- Sound Calibrator & Pistonphone Calibration

- Vibration Meter Calibration

- Vibration Calibrator Calibration

- Noise Dosimeter Calibration

- QuantumX Calibration

- Genesis HighSpeed Calibration

- Somat Calibration

- Industrial Electronics Calibration

- LAN-XI Calibration