arrow_back_ios

Main Menu

- Software

- Instrumente

- Aufnehmer

- Schwingungsprüfung

- Elektroakustisch

- Akustische End-of-Line-Testsysteme

- Simulationssysteme

arrow_back_ios

Main Menu

- Akustik

- Strom und Spannung

- Weg

- Wägezellen

- Mehrkomponenten

- Druck

- Temperatur

- Neigen

- Drehmoment

- Vibration

- Force

- Strain

- Zubehör Elektroakustikanwendung

- Künstliches Ohr

- Künstlicher Mund

- Knochenleitung

- Datenerfassung

- HATS Kopf-Torso-Simulator

- Mikrofon

- Signalaufbereitung

- Testlösungen

- Zubehör

- Aktoren

- Verbrennungsmotoren

- Betriebsfestigkeit

- eDrive

- Mobile Systeme

- Sensoren für Produktionstests

- Getriebe

- Turbolader

- Akustik

- Anlagen- und Prozessüberwachung

- Elektrische Energie

- Kundenspezifische Sensoren

- NVH

- Zuverlässigkeit

- Smarte Sensoren

- Schwingbelastung

- Virtuelle Tests

- Strukturelle Integrität

- Wägetechnik

- Druckkalibrierung | Sensor | Messumformer

- Richtlinien zur Bestimmung von Kalibrierintervallen

- Kalibrierung oder Reparatur anfordern

- Kalibrierung und Verifizierung

- Vor-Ort-Kalibrierung (Deutschland)

- Kalibrierung von Schallpegelmessern

- Kalibrierung von Mikrofone und Vorverstärker

- Kalibrierung von Beschleunigungsmessern

- Kalibrierung von Schallpegelmessern (Deutschland)

- Kalibrierung von Analysegeräten

- Eichen von Schallpegelmesser (Österreich)

- Kalibrierung von Lärmdosimetern

- Kalibrierung von Schallkalibrator und Pistonphon

- Kalibrierung des Referenzgeräts

- Kalibrierung Plus Vertrag

arrow_back_ios

Main Menu

- Weibull++ - NEW TEST (DE)

- Weibull++ - NEW TEST (DE)

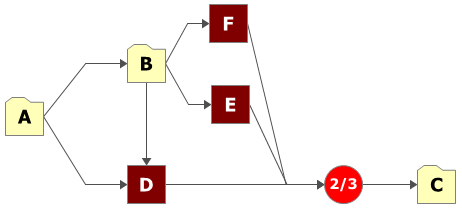

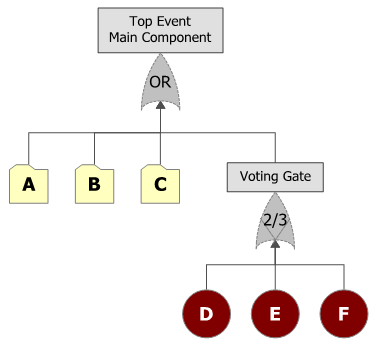

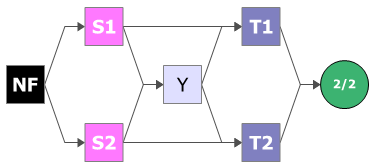

- BlockSim - New Test (DE)

- BlockSim - New Test (DE)

- XFRACAS - New Test (DE)

- XFMEA - New Test (DE)

- XFMEA - New Test (DE)

- RCM++ - New Test (DE)

- RCM++ - New Test (DE)

- SEP - New Test (DE)

- SEP - New Test (DE)

- Lambda Predict - New Test (DE)

- Lambda Predict - New Test (DE)

- Weibull++ - Accelerated Life Testing Module - New Test (DE)

- Weibull++ - Reliability Growth Module - New Test (DE)

- BlockSim - Event Analysis Module - New Test (DE)

- MPC - New Test (DE)

- Schwingungsregelungssoftware

- Zufällig

- Klassisch Schock

- Replikation von Zeitkurven

- Sine-on-random

- Random-on-random

- Synthese des Schockantwortspektrums (SRS)

- Mehrkanal-Systeme

- Einkanalige Systeme

- Piezoelektrische Paceline

- Einpress-Controller

- Verstärker mit Display

- Eichfähig

- Zubehör

- Mikrofonkapseln

- Mikrofon-Vorverstärker

- Mikrofon-Sets

- Hydrophone

- Schallquellen

- Kalibratoren

- Spezielle Mikrofone

- Zubehör

- Ladungs-Beschleunigungssensoren

- CCLD-Beschleunigungsmesser

- Kraftaufnehmer

- Referenz-Beschleunigungssensoren

- Drehzahlsensoren

- Kalibratoren

- Optische Beschleunigungsmesser

- Zubehör

- Abgekündigt

- DMS für die Experimentelle Spannungsanalyse

- Optische DMS

- DMS für den Aufnehmerbau (OEM)

- Dehnungssensoren

- Zubehör für Dehnungsmessstreifen

- DC Statische Zentriereinheit

- Stromversorgung für den Feldeinsatz

- Kabel

- Drehzapfen

- Aufstellbügel für Schwingerreger

- Akustik und Schwingungen

- Anlagen- und Prozessüberwachung

- Datenakquisition

- Elektrische Maschinen und Leistungselektronik

- Ermüdungs- und Lebensdaueranalysen

- Mechanisches Testen und Prüfen

- Wägetechnik

- Elektroakustik

- Schallquellenortung

- Umgebungslärm

- Produkt-Lärm

- Rampengeräuschprüfung

- Zertifizierung statischer Motorengeräusche

- Schallleistung und Schalldruck

- Flugzertifizierung

- Akustische Materialprüfung

- Vorbeifahrgeräusche

- Industrielle Prozesskontrolle

- Strukturüberwachung

- Produktionsprüfung und Qualitätssicherung

- Maschinenanalyse und -diagnose

- Strukturüberwachung

- Prüfungen von Schaltanlagen

- Hochspannung

- Erprobung von Antriebssträngen

- Batterieprüfung

- Elektrische Maschinenprüfung | Powertrain Testing | HBM

- Einführung in die Messung elektrischer Leistung bei transienten Vorgängen

- Transformator-Ersatzschaltbild | HBM

- Aktuelle Nulltests

- Netzprüfung | Schaltanlagenprüfung | Lösungen | HBM

- Tests im Antriebsstrang

- Schaltgeräte-Tests

- OEM Custom Sensorbaugruppen für eBikes

- OEM kundenspezifische Sensorbaugruppen für die Agrarindustrie

- Kundenspezifische OEM-Sensor-Baugruppen für medizinische Anwendungen

- Kundenspezifische Sensorbaugruppen für Robotic OEM

- Dauerhaftigkeitsprüfung - Ermüdungsprüfung

- Schock- und Falltests

- Verpackungsprüfung / Transportschwingungen

- Umweltstress-Screening - ESS

- Mechanische Satellitenqualifikation

- Buzz, Squeak und Rattle (BSR)

- Batterieprüfung für Elektro- und Hybridfahrzeuge

arrow_back_ios

Main Menu

- Gelenkköpfe

- Zugkrafteinleitungen

- Druckstücke und Lastknöpfe

- Kabel und Stecker

- Screw sets

- Zug / Druck Adapter

- Klebstoffe

- Abdeckmittel

- Reinigungsmaterial

- DMS-Kits

- Lötstützpunkte

- Weiteres Zubehör für DMS

- Kabel

- Nullpunktabgleich

- TKC-Abgleich

- TK0-Abgleich

- Testen von Freisprecheinrichtungen

- Prüfung von Smart Speakern

- Lautsprecher-Tests

- Testen von Hörgeräten

- Kopfhörer-Test

- Testen von Telefon-Headsets und -Mobilteilen

- Akustische Holographie

- Underwater Acoustic Ranging

- Akustische Tests im Windkanal — Luft- und Raumfahrt

- Windkanalprüfung für Autos

- Beamforming

- Fragen

- Identifizierung von Überfluglärmquellen

- Echtzeit-Identifizierung von Lärmquellen mit akustischer Kamera

- Abbildung der Schallintensität

- Sphärisches Beamforming

- Eisenbahn-Monitoring

- Tunnelüberwachung mit Faser-Bragg-Sensoren

- Monitoring-Lösungen für zivile Infrastrukturen

- Überwachungslösungen für Windturbinen

- Überwachungslösungen für die Öl- und Gasindustrie

- Überwachungslösungen für Eisenbahnen

- Überwachungslösungen für den Tiefbau

- Verfügbare Monitoring Services

- Fundamentüberwachung mit Dehnungsmessstreifen

- Auftragsanalyse

- Maschinendiagnose

- Gesundheits- und Nutzungsüberwachungssysteme (HUMS)

- Gasturbinenprüfung

- Fragen zur maschinellen Analyse

- Tunnel-Monitoring mit optischen Sensoren

- Monitoring-Lösungen für zivile Infrastrukturen

- Überwachungslösungen für Windturbinen

- Überwachungslösungen für die Öl- und Gasindustrie

- Überwachungslösungen für den Schienenverkehr

- Überwachungslösungen für das Bauwesen

- Verfügbare Monitoring-Services

- Fundamentüberwachung mit Dehnungsmessstreifen

- Mechanische Batterieprüfung mit Kraftsensoren

- Batterietests in der eMobilität

- Batterieprüfung in der Elektromobilität

- Mechanische Batterieprüfung mit Kraftsensoren

- Betriebsablenkungsformen (ODS)

- Klassische Modalanalyse

- Bodenvibrationstest (GVT)

- Operative Modalanalyse (OMA)

- Strukturelle Gesundheitsüberwachung (SHM)

- Test-FEA-Integration

- Schock-Reaktions-Spektrum (SRS)

- Strukturdynamische Systeme

- Fragen zur Strukturdynamik?

- Experimentelle Eigenspannungsanalyse mit dem Loch-Dril

- QuantumX Integration in ZwickRoell Prüfmaschine

- Eigenspannungen | Eigenspannungsmessung

- Elektrifizierung - Statistische Aspekte und Zuverlässigkeit (NEU)

- Elektrifizierung - Elektrische und signalverarbeitende Aspekte (NEU)

- Elektrifizierung — Mechanische und Haltbarkeitsaspekte (NEU)

- Elektrifizierung (NEU) - Auslegung und Prüfung der Lebensdauer von Strukturen für Elektrofahrzeuge

- "Elektrifizierung (NEU) - Elektrifizierung: Gewährleistung der Betriebsfestigkeit, Zuverlässigkeit und Leistung von Elektrofahrzeugen"

- Elektrifizierung (NEU) - Elektrische und Signal Nachbearbeitungstechniken für die Wechselstromanalyse in Elektrofahrzeugen

- Elektrifizierung (NEU) - Anwendung statistischer und Zuverlässigkeitstechniken zur Bestimmung der Batterielebensdauer in Elektrofahrzeugen