Reliability growth data types

Times-to-failure data

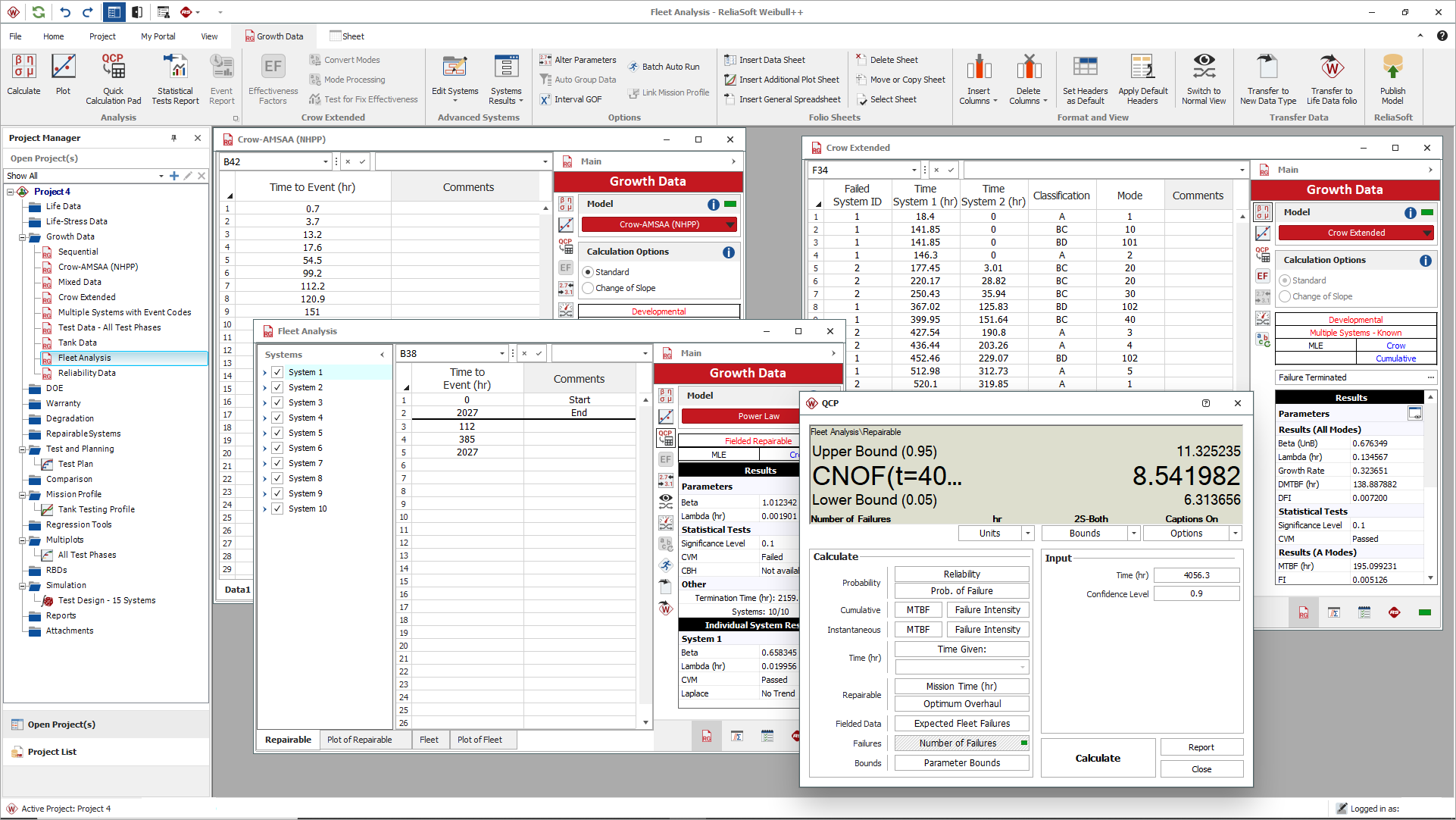

When you have data from developmental testing in which the systems were operated continuously until failure, you can use the Crow-AMSAA (NHPP) or Duane models. The module provides a choice of data types for individual or grouped failure times, and for combining data from multiple identical systems. This can include situations, where all systems operate concurrently, you have recorded the exact operating times for both the failed and non-failed systems or you have recorded the calendar date for each failure so you can estimate the operating times of the non-failed systems based on the average daily usage rate for the relevant time period.

With the Crow-AMSAA (NHPP) model, there are additional analysis options for certain situations, such as Gap analysis (if you believe that some portion of the data is erroneous or missing) or change of slope (if a major change in the system design or operational environment has caused a significant change in the failure intensity observed during testing).

Discrete data (also called attribute, one-shot or success/failure data)

When you have data from one-shot (pass/fail) reliability growth tests (and depending on the data type), the module supports mixed data models that can be used with Crow Extended and Crow Extended-Continuous Evaluation models. For discrete data, there is a choice of data types that can handle tests in which a single trial is performed for each design configuration, multiple trials per configuration, or a combination of both. The module also supports Failure Discounting, if you have recorded the specific failure modes from sequential one-shot tests.

Reliability data

When you simply wish to analyze the calculated reliability values for different times/stages within developmental testing, you can use the Standard Gompertz, Modified Gompertz, Lloyd-Lipow or Logistic models.