arrow_back_ios

Main Menu

arrow_back_ios

Main Menu

- Acústica

- Tensão e Corrente

- Deslocamento

- Força

- Células de carga

- Multicomponente

- Pressão

- Deformação

- Strain Gauges

- Temperatura

- Inclinação

- Torque

- Vibração

- Acessórios

- Controladores

- Excitadores de medição

- Excitadores modais

- Amplificadores de potência

- Sistemas Shaker

- Acessórios de Aplicação eletroacústica

- Ouvido artificial

- Boca artificial

- Condução óssea

- Aquisição de dados

- Simulador de cabeça e torso HATS

- Microfone

- Condicionamento de sinal

- Soluções de teste

- Acessórios

- Atuadores

- Motores de combustão

- Durabilidade

- eDrive

- Sistemas móveis

- Sensores de teste de produção

- Caixas de transmissão

- Turbo Charger

arrow_back_ios

Main Menu

- Software de controle de vibração

- Aleatório

- Classical Shock

- Replicação da forma de onda temporal

- Sine-on-Random

- Random-On-Random

- Síntese do espectro de resposta ao choque

- Sonômetro

- Medidores de vibração

- Medidores de intensidade sonora

- Dosímetros de ruído

- Software

- Acessórios

- Sistemas multicanais

- Sistema de canal simples

- Piezoelectric Paceline

- Controladores Press Fit

- Amplificadores com display

- Legal for Trade

- Acessórios

- Cartuchos de microfone

- Pré-amplificadores de microfone

- Conjuntos de microfones

- Hidrofones

- Fontes sonoras

- Calibradores

- Microfones especiais

- Acessórios

- Acelerômetros de carga

- Acelerômetros CCLD

- Transdutores de força

- Acelerômetros de referência

- Sondas de tacômetro

- Calibradores

- Acelerômetros ópticos

- Acessórios

- Descontinuado

- Unidade de centralização estática DC

- Fontes de alimentação de campo

- Cabos

- Pinhões

- Suportes de excitação

- Acústica e vibração

- Monitoramento de ativos e processos

- Data Acquisiton

- Teste de energia elétrica

- Ensaios de fadiga e durabilidade

- Ensaio mecânico

- Confiabilidade

- Pesagem

- Ruído do produto

- Teste de ruído de rampa

- Certificação do ruído estático do motor

- Certificação de voo

- Ruído de passagem de veículos

- Electroacoustics

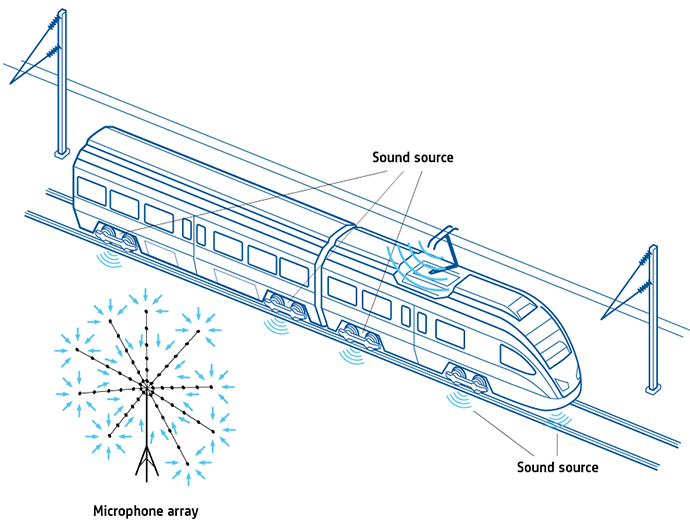

- Identificação da fonte de ruído

- Ruído ambiental

- O que é potência sonora e pressão sonora

- Certificação de ruído

- Teste de Material Acústico

- Teste de produção e garantia de qualidade

- Análise e Diagnóstico de Máquinas

- Monitoramento de integridade estrutural

- Testes de quadros de distribuição

- Alta tensão

- Teste de trem de força

- Teste de bateria

- Teste de máquinas elétricas | Teste de Powertrain | HBM

- Introdução à Medição de Energia Elétrica Durante Transitórios

- Diagrama de circuito equivalente do transformador | HBM

- Teste zero atual

- Conjuntos de sensores personalizados OEM para eBikes

- Conjuntos de sensores personalizados OEM para a indústria agrícola

- OEM Custom Sensor Assemblies para aplicações médicas

- Conjuntos de sensores personalizados para OEM de robótica

- Sensores OEM para a indústria agrícola

- Sensores OEM para aplicações robóticas e de torque

- Sensores médicos OEM

- Teste de Durabilidade - Teste de Fadiga

- Teste de choque e queda

- Teste de embalagens / Vibração de transporte

- Triagem de Estresse Ambiental - ESS

- Qualificação de Satélites Mecânicos

- Zumbido, chiado e chocalho (BSR)

- Teste de bateria de veículos elétricos e híbridos

arrow_back_ios

Main Menu

- Testing Of Hands-Free Devices

- Smart Speaker Testing

- Teste de alto-falante

- Teste de aparelhos auditivos

- Teste de auscultadores

- Testes de fones de ouvido e telefones

- Perguntas

- Holografia acústica

- Variação acústica subaquática

- Teste acústico de túnel de vento – Aerospace

- Ensaios em túnel de vento para automóveis

- Beamforming

- Identificação da fonte de ruído

- Identificação de fontes de ruído em tempo real com câmara acústica

- Medidores de intensidade sonora

- Formação de feixe esférico

- PRODUCT NOISE

- Sistema de Medição Acústica

- Acústica de salas e edifícios

- Sistema de medição arquitetónica

- Ruído no local de trabalho

- Poluição sonora urbana

- Potência sonora baseada na intensidade do som

- Pressão sonora - Reverberação Potência sonora baseada na sala

- Certificação de ruído estático do motor

- Ruído Pass-by de Veículos

- Ensaio de ruído de rampa

- Certificação de Voo

- Análise de Pedidos

- Diagnóstico de Máquinas

- Sistemas de monitoramento de integridade e uso (HUMS)

- Teste de turbinas a gás

- Perguntas para análise de máquinas

- Monitoramento de túneis com sensores Fiber Bragg

- Soluções de monitoramento para infraestruturas civis

- Soluções de monitoramento para turbinas eólicas

- Soluções de monitorização para a indústria do petróleo e do gás

- Soluções de monitoramento para ferrovias

- Soluções de monitoramento para engenharia civil

- Serviços de monitoramento disponíveis

- Monitorização de fundações utilizando extensómetros